PICK & PLACE SYSTEM – THE KEY ELEMENT OF ANY PCB ASSEMBLY LINE!

Introduction

The advent of technology has already brought tremendous benefits to the electronics industry. Pick and Place (P&P)is one such boon to the Surface Mount Technology. In fact, it can be credited for being a part of the success of SMT.

Due to manual placement in the PCB assembly line, the process becomes slow and relatively inaccurate which ultimately affects the throughput and quality. Therefore, to eliminate these stumbling blocks, P&P has taken and secured its position in the PCB assembly process.

In layman’s terms, Pick and Place machines at placing surface mount components as accurately and quickly as possible.

In technical terms, the placement of surface mount technology (SMT) components on printed circuit boards (PCB) and its assembly task involves the following steps:

-

Grip the right component from the pick-up position i.e. feeder

-

Place the component on the parking position (target position) on the surface of printed circuit boards (PCB) with appropriate precision and accuracy

Some high-density electronic circuit boards include hundreds or even thousands of SMT components. A good bit of these are tiny components, and a majority requires very accurate placement. However, it is not feasible to place them manually. Here is why the pick and place machine comes into the picture as it places all the components accurately and in a repeatable fashion.

Role pick & Place:

In SMT PCB assembly, there are three major processes. Solder paste, Pick & Place assembly, and reflow method for solder joints.

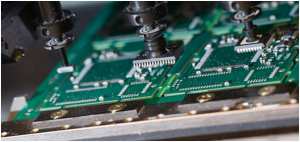

After solder paste is applied, a conveyor will transport PCB’sto to the placement area and clamp. Furthermore, the reference position of PCB is determined by the machine with the help of fiducial marks*and then the component placement program starts.

-

There are many feeds on either side of the machine where components are loaded. The component placement process consists of picking each component from the reel/tube/IC stack in turn from a feeder using a nozzle head (a small vacuum) and transporting it to the programmed position i.e.onto the board.

-

The head is precisely controlled by the software and uses machine vision to ensure that everything is placed in exactly the right position. Accurate positioning is of paramount importance as some components are very small and solder pads are very narrow.

-

Each type of placement machine has its own format for programs. The pick and place machines are pre-programmed with the information about component positions including – part numbers, circuit board reference, rotation, package information, and X/Y position.

The assembly is unclamped post-completion and transported by conveyor to the next machine in the line.

*Fiducial Marks – Fiducial marks are simply little target shapes within the tracklayer of the PCB that are positioned where they cannot be confused with other aspects of the board design. These marks are used by Pick & Place to find PCB board placement offset. PCB assembly service which is considered as one of the most challenging aspects of electronic product design can be very generously provided by PCB assembly companies in Gujarat.

Leave a Reply