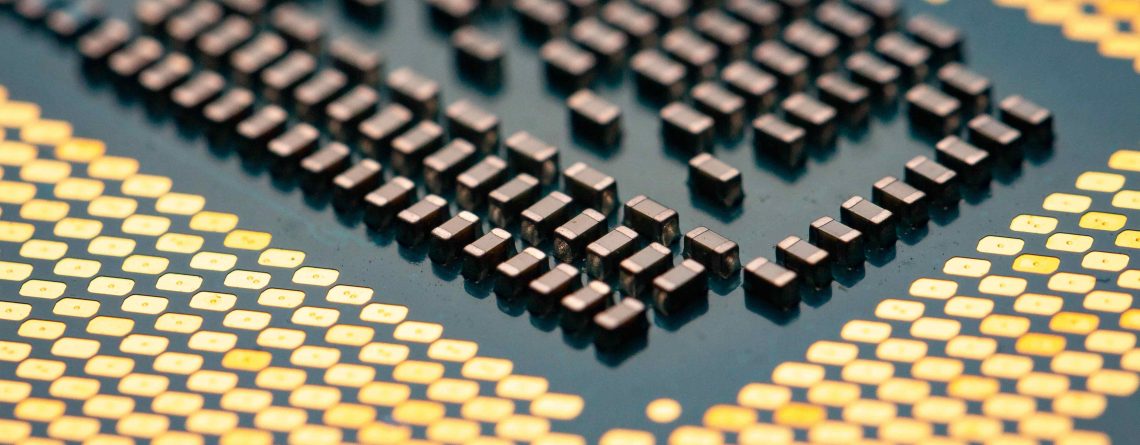

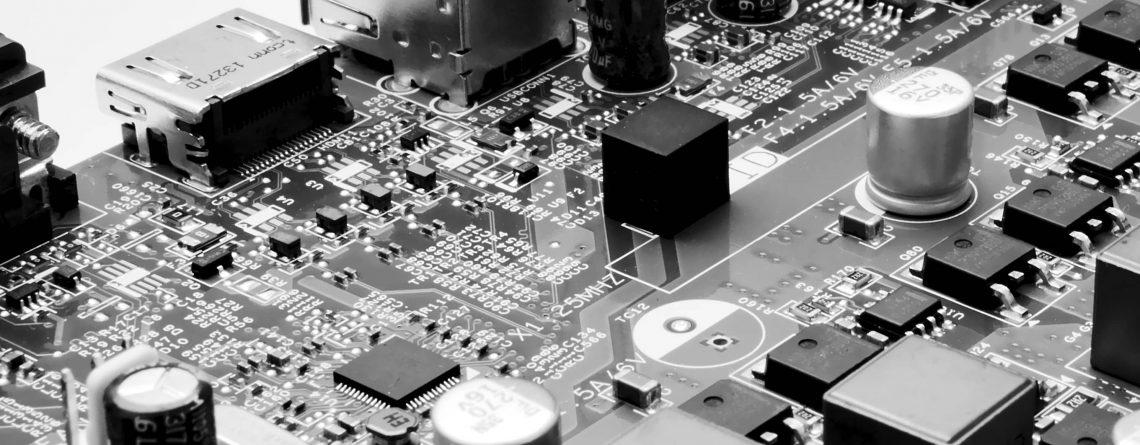

Considering SMT for mass production

SMT for mass production excellence is about speed, quality, and cost. To meet your dynamic market needs, your company should be able to pivot based on changing demand levels. At a time, "Through-Hole" technology dominated the manufacturing market as it was a huge step forward from hand-crafted solutions, but this still had significant problems. Despite...